Do you have a thing for cute printed t-shirts or custom-printed mugs? All of those popular prints are mostly either screen prints or sublimation prints.

Now, wait a second. Aren’t those two the same?

Wrong. There’s a vast difference between the screen printing and the sublimation process.

Here’s what screen printing vs sublimation looks like.

Screen printing is a printing method where ink stains the top of the substrate whereas sublimation embeds the ink into the material. So, this makes screen printing less durable than sublimation printing. However, screen printing is great if you have to print in bulk. On the contrary, sublimation is cost-efficient even for custom single orders.

This is just a small overview of the differences between screen printing and sublimation. Keep reading the segments below to learn more about the differences, interesting facts, and business opportunities between the two printing processes.

What is Screen Printing?

Screen printing is the process of printing stenciled designs on a flat surface by forcing the ink manually through a mesh screen. Depending on the type of ink, you can screen print on almost any kind of surface such as fabric, wood, metal, paper, plastic, and glass.

It’s a popular technique in the garment industry since you can create large batches of fabrics with the same print in a few hours.

Process of Screen Printing

It takes 4 major steps to complete the whole process of screen printing. These are creating a design, preparing a mesh screen, creating a stencil, and finally, printing the stenciled design on the surface.

Here’s how to do it from scratch:

Step 1: First, you need to create your preferred design on your computer and print it on a transparent acetate film through a printer.

Step 2: Then, choose a mesh screen depending on the detailing of the print and your budget. If your design is more intricate, you should go for a mesh screen with a high mesh count.

On the other hand, if the design requires a wide space for filling up with ink, you should select a low-count mesh screen.

Step 3: As soon as the mesh screen is ready, put a coating of light-reactive emulsion layer on it. This will allow the stenciled design to transfer on the mesh screen in the presence of bright light.

Step 4: After that, carefully place the acetate film on the mesh screen under a bright light and wait for the emulsion to harden. If the design is more intricate and has multiple colors, you should use multiple mesh screens in that case.

[Note: Generally, it takes around 4 hours to dry the emulsion at room temperature. If you use a dark room without direct light and heat, it’ll take around 1-2 weeks. However, it’ll only take around 20 minutes if you use a screen room drying cabinet.]

Step 5: So, after the emulsion is completely dried off, you need to add some final touch-ups in case the print is missing in the detailed areas. This is how you create the stencil for screen printing.

Step 6: Now, you have to keep your substrate (fabric, paper, etc.) flat on a printing board exposing the top part where you’ll print the design.

Step 7: After that, gently put the screen on top of the substrate. Apply your preferred colored ink on the screen and even out the ink with a squeegee. Eventually, the ink will transfer through the stencil to the material.

Step 8: Once you finish using the stencil, you should wash the emulsion off with a washing fluid. Washing will help you to reuse the stencil for a different screen printing project.

Step 9: Finally, place the substrate inside a dryer to heat-curate the print. At the end of the process, you’ll get a long-lasting screen print that won’t fade away easily even after 40-50 washes.

So, this is how you screen print on a substrate.

Advantages of Screen Printing

Screen printing is actually a $9.3B industry in 2023. The reason it’s so profitable is that it provides the advantages given below:

- You can print a large batch of products in less time using screen print.

- It’s a cost-effective and low-effort process.

- It creates vibrant prints on garments with a smooth and durable finish.

- Screen printing is faster than the heat pressing process in the garments section.

- Other than fabrics, you can also screen print on any kind of material like wood, glass, paper, plastic, and metal.

Disadvantages of Screen Printing

Apart from the advantages, screen printing also has some drawbacks. Here are the disadvantages of screen printing listed below:

- Screen printing is a costly method when you need to print on a small batch of items.

- For multi-colored designs, screen printing becomes expensive.

- In case of any mistakes, it’s difficult to remove screen printing from a material.

- Screen printing requires more steps than other printing methods. For beginners, it can be a complex and time-consuming process.

- Screen printing wastes a lot of water which isn’t eco-friendly.

Now that you know about screen printing, you should clear your concepts about sublimation too.

What is Sublimation?

Sublimation is a printing process that helps to transfer ink from sublimation paper to fabric using heat. During this process, the dye changes from a solid state to a gaseous form and imprints straight on the fabric material.

As the dye directly embeds in the fabric, you can print multiple colors with intricate designs and patterns. It’ll look almost like a duplicate of the design.

However, if you fail to put enough heat pressure (300℉-400℉), you’ll receive a faded print on the fabric. Also, following the wrong steps will lead to disintegrated patterns and white creases.

You don’t want that! So, to keep you enlightened about the correct process, I’ve put together a small step-by-step sublimation guide in the next segment.

Process of Sublimation

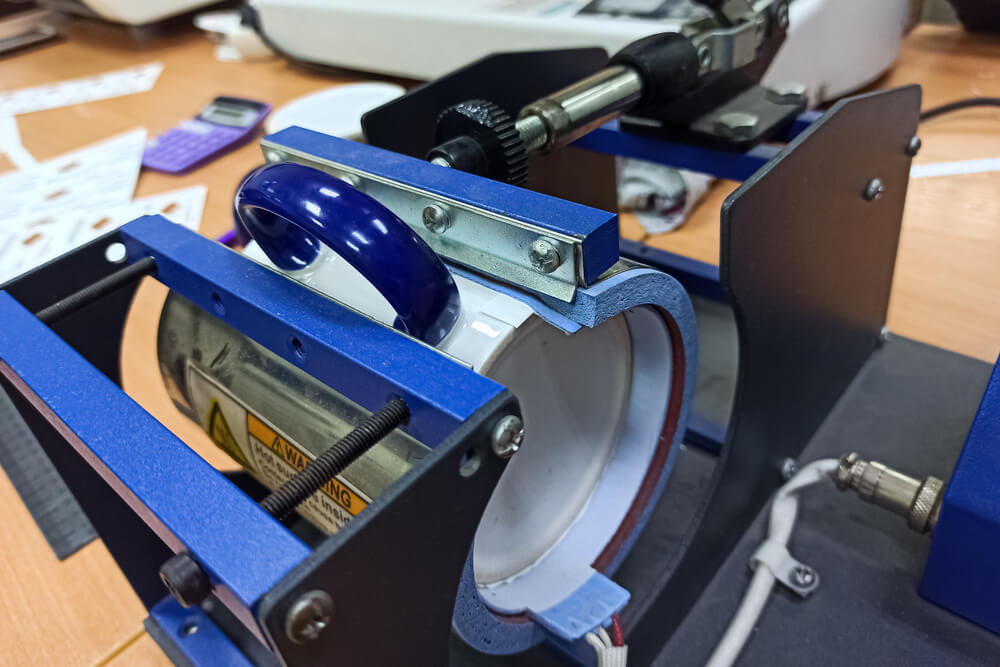

If you want to do sublimation printing on your own, you’ll need 5 major pieces of equipment. These are a sublimation printer, sublimation inks, sublimation transfer paper, heat-resistant papers, heat-safe tapes, and a heat press.

After gathering all the required equipment and the material you want the printing on, here are the steps you need to follow.

Step 1: First you have to create a design that you want to print. It can be either a photograph or a digital image.

Step 2: Next, fill in the sublimation inks inside the sublimation printer. Then, print the selected image or design on a sublimation transfer paper.

Step 3: Set the heat press to 400℉ and let it heat up for 60 seconds.

Step 4: As soon as the heat press is warmed up, you need to place your fabric on the heat press carefully. Remove any wrinkles using your hand or a lint roller.

Step 5: Then, put the designed printed sublimation transfer paper on top of the fabric in the desired spot. Secure the edges of the paper using heat tape on the sides. After that, you have to lay down the heat-resistant paper on the sublimation paper.

Step 6: Finally, clamp the heat press down, and let it sit for 40-75 seconds. Then, pull up the heat press and remove the sublimation transfer paper immediately.

Voila! Your sublimation print is ready!

Advantages of Sublimation

The sublimation process is a blessing for modern print designers. Here are some of the major advantages of sublimation.

- You can dye complex and intricate designs with sublimation on both sides of your fabric.

- You don’t need to pay extra for adding multiple colors to the design.

- Apart from dying fabrics, you can also sublimate custom designs on vinyl, ceramic, metal, and cured wood.

- Sublimation designs remain protected even after multiple washes. The dye doesn’t peel off, fade, or crack.

- This process embeds the dye directly inside the material. So, you can’t feel any layer of dye on your skin.

- It’s an efficient and cost-effective solution for printing small-quantity items.

Disadvantages of Sublimation

Though sublimation has numerous benefits, it has some drawbacks too. The disadvantages of sublimation are listed below.

- You can’t run the sublimation process on any kind of fabric. It only supports polyester including knit fabrics and woven fabrics.

- You can’t dye dark objects lighter with sublimation printing. But you can do the opposite.

- Both sublimation printers and heat presses are expensive. So, the overall sublimation process becomes more costly than any other printing method.

Sublimation vs Screen Printing: 18 Key Differences [Explained]

Sublimation and screen printing differs in every aspect regarding the printing process, ink type, material compatibility, durability, production speed, design complexity, print finish, and cost-effectiveness.

These differences are described below.

1. Printing Process

The major difference between sublimation and screen printing is the printing process.

Sublimation is almost an automated process whereas in screen printing you have to rely on manual labor.

That’s why it takes more time to print in the screen printing process than printing through sublimation.

| Printing Process | Screen Printing | Sublimation |

|---|---|---|

| Technique | Uses stencil/mesh screen for ink transfer. | Uses heat to transfer dye onto substrate. |

| Suitable Materials | Works on fabric, paper, plastic, metal. | Primarily used on polyester and coated substrates. |

| Color Options | Wide range of vibrant, opaque colors. | Full-color, high-res prints with unlimited colors. |

| Durability | Excellent durability, withstands washes/use. | Good durability, prints may fade over time. |

| Cost | Cost-effective for large-volume production. | More expensive for small quantities, but cost-effective for larger quantities. |

2. Ink Type

Now, the type of ink also matters in both sublimation and screen printing methods.

In dye Sublimation vs. Screen Printing, Sublimation uses a special dye known as disperse dye which you can’t use in screen printing. This type of dye is capable of turning into a gaseous form from a solid state at 400℉.

On the other hand, water-based inks, discharge inks, and plastisol inks are commonly used in screen printing.

| Ink Type | Screen Printing | Sublimation |

|---|---|---|

| Plastisol | Yes, commonly used in screen printing. | Not applicable. Sublimation uses dye-sublimation ink. |

| Water-based | Yes, an alternative to plastisol, environmentally friendly. | Not applicable. Sublimation uses dye-sublimation ink. |

| Discharge | Yes, used for a softer feel, especially on dark garments. | Not applicable. Sublimation uses dye-sublimation ink. |

| Specialty Inks | Yes, options available like metallic and glow-in-the-dark inks. | Not applicable. Sublimation uses dye-sublimation ink. |

| Dye-Sublimation Ink | Not applicable. Screen printing does not use dye-sublimation ink. | Yes, specifically formulated for sublimation printing. |

3. Color Range

As dye types varies, the limitation of using colors also differs in the case of both sublimation and screen printing.

For sublimation, the ink color must be among the 4 basic CMYK colors – cyan, magenta, yellow, and black. These four basic colors will mix and match while printing and eventually duplicate the exact color of your design.

But in the case of screen printing, there are no such limitations. You can use any color you want.

| Color Range | Screen Printing | Sublimation |

|---|---|---|

| Vibrant Colors | Yes, offers a wide range of vibrant and opaque colors. | Yes, produces full-color prints with unlimited color options. |

| Specialty Inks | Yes, can use specialty inks like metallic and glow-in-the-dark. | Not applicable. Sublimation uses dye-sublimation ink. |

| Photographic Prints | Limited. Can achieve high-quality prints but may require halftones or CMYK process. | Excellent. Sublimation allows for high-resolution photographic prints. |

| Color Accuracy | Good color accuracy, but slight variations may occur due to manual mixing. | Excellent color accuracy, reproduces colors with precision. |

4. Material Compatibility

You can’t sublimate on 100% cotton fabrics as you can do with screen printing. The sublimation process only supports polyester materials.

You can also sublimate on nylon, lycra, spandex, and neoprene fabrics. But for cotton and silk fabrics, screen printing produces the best results.

Apart from fabrics, both of the printing processes are compatible with other materials. Sublimation works best on ceramic, enamel, and cork-backed coasters whereas screen printing does magic on wood, metal, and plastic.

| Material Compatibility | Screen Printing | Sublimation |

|---|---|---|

| Fabric | Yes, works well on various fabrics such as cotton, polyester, and blends. | Yes, primarily used on polyester fabrics and polyester-coated substrates. |

| Paper | Yes, suitable for printing on paper materials. | Yes, can be used on paper materials. |

| Plastic | Yes, compatible with various types of plastic substrates. | Yes, compatible with certain types of plastic substrates. |

| Metal | Yes, can be used on metal substrates. | Yes, compatible with certain types of metal substrates. |

5. Durability

Speaking of durability, sublimation lasts longer than screen printing. It’s because the ink gets absorbed in the material during sublimation by using a heat press. So, even after multiple washes, the design and ink remain intact. This makes the ink last for a long period of time in the material.

Now, the screen printing process also heats and curates the ink at the end. But in this case, the ink does not embed in the material. You can actually feel the dried ink texture on your hands after screen printing.

So, after a few washes, the ink starts cracking or fading. This makes the screen printing process less durable than the sublimation process.

| Durability | Screen Printing | Sublimation |

|---|---|---|

| Wash Resistance | Excellent durability, prints can withstand repeated washes and use. | Good durability, but prints may fade over time, especially with excessive heat or sunlight exposure. |

| Abrasion Resistance | Provides good resistance to abrasion and can maintain print quality. | Provides good resistance to abrasion and maintains print quality. |

| Cracking or Peeling | Minimal risk of cracking or peeling, especially with proper curing. | Minimal risk of cracking or peeling, as the dye becomes part of the material itself. |

| Outdoor Durability | Good outdoor durability, resists fading and weathering to some extent. | Moderate outdoor durability, prints may fade over time when exposed to prolonged sunlight and harsh weather conditions. |

6. Production Speed

If you want to calculate the production speed, sublimation takes less time to print than the screen printing process.

For sublimation, it’ll take around 1 minute to print one shirt whereas it’ll take approximately 5-6 minutes for screen printing.

Again, you’ll need to add 5-10 minutes extra for the drying process in case of sublimation. For screen printing, it can go from 20 minutes to 4 weeks depending on the type of dye and humidity in the environment.

| Production Speed | Screen Printing | Sublimation |

|---|---|---|

| Setup Time | Longer setup time due to the preparation of screens and stencils. | Relatively quick setup time as no screens or stencils are required. |

| Printing Speed | Fast printing speed once the setup is complete, especially for large quantities. | Relatively fast printing speed, especially for full-color designs, but slightly slower than screen printing. |

| Multicolor Prints | Requires separate screens and setup for each color, which can increase production time. | Can produce multicolor prints in a single pass, reducing production time for complex designs. |

| Turnaround Time | Longer turnaround time for complex designs or small quantities due to setup and color registration. | Shorter turnaround time, especially for large quantities or full-color prints. |

7. Design Complexity

For complex designs, sublimation is better than screen printing. Sublimation directly pastes the design on the material with a heat press. So, the design comes out almost similar to the original design.

But in screen printing, you must add different layers of inks for different colors and patterns. It’ll create extra layers of ink which will destroy the texture of the print.

The mesh screen in screen printing also acts as a block for intricate designs. If the mesh screen has bigger gaps than the design’s pattern gap, it’ll ooze out more ink that will cover up the design. This will eventually ruin the print pattern and texture.

| Design Complexity | Screen Printing | Sublimation |

|---|---|---|

| Simple Designs | Well-suited for simple designs with fewer colors and solid shapes. | Can handle simple designs effectively. |

| Detailed Artwork | Can reproduce detailed artwork, but may require halftones or higher mesh count screens. | Excellent for reproducing intricate details, including gradients, fine lines, and photorealistic images. |

| Fine Text | Can print fine text, but may require higher mesh count screens for optimal results. | Can produce sharp and legible text, even at small sizes. |

| Overlapping Colors | Can handle overlapping colors, but registration can be challenging for complex designs. | Can easily reproduce designs with overlapping colors, gradients, and complex color transitions. |

8. Cost-Effectiveness for Small Orders

Sublimation is more cost effective than screen printing for small orders. You can print only one item at a time and it won’t be too expensive for you than creating a large batch. That’s why sublimation is more suitable for custom gift products.

On the contrary, it’s expensive and time-consuming to create small batches at a time in the case of screen printing. As you need to apply manual labor here, creating small orders will increase your production cost more than creating bulk orders.

| Cost-Effectiveness for Small Orders | Screen Printing | Sublimation |

|---|---|---|

| Setup Costs | Higher setup costs due to the creation of screens and stencils. | Lower setup costs as no screens or stencils are required. |

| Printing Costs | Can be relatively higher for small orders due to setup and labor costs. | Can be relatively higher for small orders due to ink and paper costs. |

| Quantity Considerations | More cost-effective for large quantities as setup costs can be spread across more items. | More cost-effective for larger quantities due to lower setup costs per item. |

| Pricing Flexibility | May have limited flexibility in pricing for small orders due to higher setup costs. | Offers more flexibility in pricing for small orders due to lower setup costs. |

9. Printing on Dark Fabrics

If you follow the traditional methods, you can’t sublimate on dark fabrics like you can do with screen printing. Sublimation works best for white or light-colored substrates.

However, if you think about htv vs sublimation vs screen printing, it’s possible to sublimate dark fabrics by using white heat transfer vinyl. You need to sublimate on top of the vinyl in this case.

Well, there are no difficulties like this in screen printing. You can easily print on dark fabrics.

| Printing on Dark Fabrics | Screen Printing | Sublimation |

|---|---|---|

| Opacity of Prints | Excellent opacity, vibrant and opaque prints on dark fabrics. | Limited opacity on dark fabrics, resulting in a subtle, “vintage” look. |

| Underbase Requirement | Requires an additional layer of white ink (underbase) for color vibrancy. | No underbase requirement, as sublimation inks directly dye the fabric. |

| Print Feel | Thicker ink layer on dark fabrics. | Thin and lightweight print, maintaining the fabric’s natural feel. |

| Color Limitations | Wide range of colors, including vibrant and opaque shades. | Limited color options due to the translucency of sublimation inks. |

10. Environmental Impact

Sublimation is more eco-friendly than the screen printing process. It’s because sublimation uses non-toxic inks whereas screen printing uses non-biodegradable inks like plastisol. But you can also find water-based inks for screen printing that are less harmful to the environment.

Sublimation also uses less water compared to screen printing. So, there’s less waste produced and exposure to the environment.

On another note, you can’t reuse the sublimation waste further. But you can create creative patterns on different kinds of products (e.g., headbands) out of sublimation waste.

| Environmental Impact | Screen Printing | Sublimation |

|---|---|---|

| Ink Usage | Uses more ink, resulting in higher ink consumption. | Uses less ink overall due to the transfer process. |

| Chemicals | May require the use of chemicals for screen preparation and cleanup. | Generally fewer chemicals involved, especially with water-based sublimation inks. |

| Waste Generation | Produces more waste due to unused ink, screens, and stencil disposal. | Generates less waste as sublimation inks are transferred completely. |

| Energy Consumption | Requires more energy for setup, curing, and drying processes. | Requires less energy for the printing and heat transfer process. |

11. Print Size Limitations

Both sublimation and screen printing have print size limitations as they are heavily dependent on machinery. But you can print large-sized items through sublimation than screen printing.

You can print more than 44 or (111.76 cm) inches with a sublimation printer. On the contrary, screen printing can produce up to 28 inches or 71.12 cm at best with a large printing press.

12. Production Setup Costs

Sublimation production costs less to set up compared to screen printing. You can start a sublimation business having a budget of less than $1500. But for screen printing, you need to keep at least $1030 in hand. It can cost up to $3,618 for a screen printing setup alone.

The reason screen printing production costs more than sublimation is using multiple pieces of equipment in the process. Apart from a screen mesh, you’ll have to spend on a good printer, screen printing frames, ink, emulsion, squeegee, and a heat gun.

But for sublimation, you’ll need a printer, heat press, sublimation ink, and heat-resistant paper.

Mind that high-quality sublimation printers and heat presses can be pretty expensive starting from $500. When the printers and heat presses are expensive, sublimation production costs can be higher than screen printing costs.

13. Image Resolution

To get the best printing results, you’ll need to print a higher PPI image for screen printing than for sublimation. Having an image resolution of 355 PPI would produce the best screen printing design.

On the other hand, you can get a great image resolution with only 300 PPI in the sublimation process. I suggest keeping the resolution between 200 to 300 PPI. But don’t go below 200 PPI. Otherwise, you’ll have faded or blurry images printed on your substrate.

| Image Resolution | Screen Printing | Sublimation |

|---|---|---|

| Resolution Capabilities | Can achieve high-resolution prints, but intricate details may require halftones or higher mesh count screens. | Excellent resolution capabilities, capable of reproducing intricate details, gradients, and photorealistic images. |

| Fine Lines | Can print fine lines, but the level of detail may depend on the mesh count and screen quality. | Can reproduce fine lines with sharpness and clarity, even at small sizes. |

| Text Clarity | Text can be sharp and legible, but smaller text may require higher mesh counts for optimal results. | Produces sharp and legible text, even at smaller sizes. |

| Photographic Quality | Can achieve good photographic quality, but halftones or CMYK process may be necessary for optimal results. | Excellent photographic quality, capable of reproducing high-resolution photographs with accuracy. |

14. Print Texture and Finish

You can feel the print texture of screen printing designs. But it’s the opposite when it comes to sublimation. The ink gets completely blended in with polyester or other sublimation-approved materials.

This makes the sublimation print more smooth and seamless whereas the screen print texture is more prone to cracks and peels.

15. Quality of Gradients

In the case of creativity, screen printing wins the battle with sublimation. Though adding multiple colors is a hectic task in screen printing, you can add glitters and special gold/silver inks to create an interesting visual.

But it’s quite impossible to add a glittery effect in sublimation. Though you can pull off a gradient-style design with the printer, it won’t look as vibrant as the screen printing gradient.

16. Ability to Print Metallic Colors

Another interesting difference between sublimation and screen printing is that sublimation can’t print metallic colors while screen printing can. It’s not possible to inject metallic inks in sublimation printers.

But you can create a metallic finish on sublimation printing through Premium Holographic and Metallic garment films. All you need to do is heat press the films on the substrate 3-4 times at multiple (150℃/ 180℃) temperatures. They will create a metallic finish on your item just like screen printing.

17. Ink Saturation Levels

It’s a tie between sublimation and screen printing regarding ink saturation levels. It’s because the saturation level depends on the type of substrate and ink.

For example, fabrics have high ink saturation levels than metal or wood substrates. Again, plastisol inks have high saturation levels compared to water-based inks.

So, if you’re using water-based ink while screen printing, the ink saturation will be less than when you’re dye-sublimating.

| Ink Saturation Levels | Screen Printing | Sublimation |

|---|---|---|

| Saturation Range | Offers a wide range of ink saturation levels, allowing for vibrant and intense colors. | Provides a moderate level of ink saturation, resulting in a slightly softer and more natural look. |

| Color Intensity | Can achieve highly saturated and vibrant colors, especially on light-colored fabrics. | Offers good color intensity, particularly on lighter fabrics, but may appear slightly muted on darker fabrics. |

| Layering Capability | Allows for layering of multiple ink colors to achieve desired saturation levels and color effects. | Layering is not applicable to sublimation, as inks directly dye the fabric, limiting the ability to adjust saturation through layering. |

| Color Consistency | Provides consistent ink saturation levels across prints and production runs. | Offers consistent ink saturation levels, ensuring uniformity in color reproduction. |

18. The Vibrancy and Color Accuracy

As sublimation directly blends on the substrate, it’s capable of producing more accurate color than screen printing. The color is more vibrant and keeps intact for years. On the other hand, screen printing colors crack after a few washes.

Comparison Table – Screen Printing Vs Sublimation

Here’s a head-to-head comparison table on the differences between screen printing and sublimation.

| Key Differences | Screen Printing | Sublimation |

| Quality | High-quality and textured finish | Premium quality finish with ink embedded in the substrate |

| Durability | Cracks and peels off over time | Colors remain intact for years |

| Printing Complexity | Difficult to print intricate designs | Easy to print any kind of designs |

| Color Options | One or two color combos provide the finest finish | Doesn’t degrade the quality using more than 2 colors |

| Set-up Time | Takes time to set up | Requires almost no time at all to set up |

| Substrates | Cotton fabric, wood, silk, and paper | Polyester, ceramic, vinyl, metal, and cured wood |

| Cost-Efficiency | Cost-efficient for bulk orders only | Cost-efficient for both small and large orders |

| Environmental Impact | Produces unusable toxic waste | Produces reusable biodegradable waste |

Printers – Screen Printing Vs Sublimation

2 Best Printer for Screen Printing

HP OfficeJet Pro 9015

After testing out multiple printers for screen printing, the HP OfficeJet Pro 9015 color printer stood out to me the most. It can not only produce outstanding image quality but also saves a lot of time.

It has a printing speed of 22 ppm for monochrome images and 18 ppm for colorful prints. This means you can save hours on printing designs and start working on your screen printing projects.

But what stood out to me the most is the smart app connected to the printer. It makes the process seamless and efficient.

HP also delivers ink cartridges for this printer at almost half the cost of the original price. So, you can go save up money for buying that extra donut for yourself. The printer also supports Wi-fi and has data encryption policies to secure your privacy.

However, did find the scanner sometimes not picking up on the finer details. But for screen printing, it’s best if you keep the design simple. So, this drawback isn’t a big trouble.

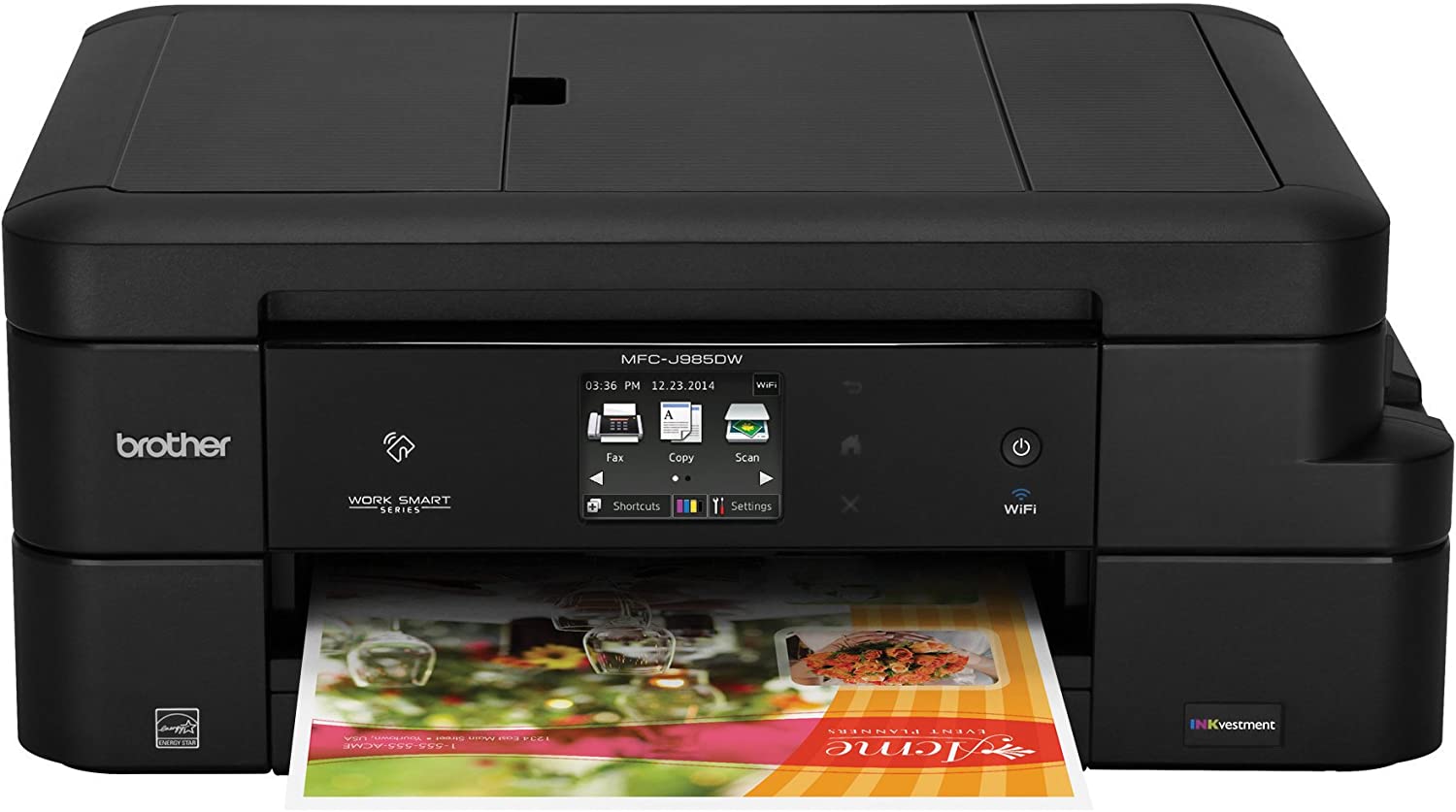

Brother Inkjet Printer, MFC-J985DW

Another noteworthy inkjet printer is the Brother Inkjet MFC-J985DW Printer. It’s a low-cost printer with excellent photo print quality. You can print vibrant images with this color printer in a matter of seconds.

Speaking of the print quality, the Brother Inkjet MFC-J985DW does a good job when it comes to printing graphics on paper. Though the yellow seems a little bit faded, it’s barely noticeable combined with other colors. The text print is also equally appealing except if you print really small fonts.

The maximum print speed for both monochrome and color printing is 10 ppm which is lower than the HP OfficeJet Pro 9015 I reviewed above. Still, I found it speedy (5-10 seconds/page) enough to get my screen printing projects done faster than before.

It’s also a money-saving printer that gives you the liberty to print 2400 monochrome pages under $25 and 1200 pages under $15. Overall, it’s a cost-efficient printer for screen printing.

2 Best Sublimation Printer

Sawgrass SG500 Sublimation Printer

I’ll start off with one of the most beginner-friendly yet efficient sublimation printers – the Sawgrass SG500 Sublimation Printer. It has a simple interface that even a novice can use it.

I’ve used this printer for 6 months as a sublimation hobbyist. Compared to other printers like Epson, I found it best for saving time. It has a built-in automatic cleaning routine which helps with maintenance issues.

But the best part is getting a Print Manager and a CreativeStudio bundle with this printer. It helps tremendously in creating images without buying additional designing software like Adobe Photoshop or Canva.

The Sawgrass SG500 only has an 8.5” x 11” print size limit. It’s best for sublimating on small objects like mugs, phone cases, and coasters. But if you need a larger size (up to 8.5” x 51”), you need to add a bypass tray.

Though it’s a bit pricey (over $600), it’s a good deal as you you don’t have to replace the inks too often.

Sawgrass SG1000 Sublimation Color Printer

Here’s another outstanding performer from Sawgrass – the Sawgrass SG1000 which provides excellent print quality. It’s renowned for its energy-efficient capability.

The printer can print up to 11″x17″ print size with a standard tray and 13″x51″ with a Bypass Tray. This means you can use the Sawgrass SG1000 for large sublimation projects like creating a banner or sublimating on a large canvas, unlike the Sawgrass SG500.

Speaking of print quality, the Sawgrass SG500 can print images at 4880×1200 DPI. The high-quality upgraded Sublijet-UHD ink is responsible for creating clear and vibrant images.

This sublimation printer also supports CreativeStudio, Print Manager, Photoshop, CorelDraw, and Adobe Illustrator for creating awesome designs.

Now, if you compare this Sawgrass SG1000 with other sublimation printers like the SG500, it will seem like an expensive deal (above $1500). But considering its upgraded features, it’s the best investment for sublimation startups.

Inks – Screen Printing vs Sublimation

2 Best Screen Printing Inks

Speedball Fabric Screen Printing Ink

Considering ink quality, durability, and price, Speedball Fabric Screen Printing Ink is my personal favorite among all the water-based inks. Whether you’re working on paper, fabric, or cardboard, this ink stains the substrate like a pro screen printing finish.

It includes 6 colors in the package consisting of all the basic colors – Black, White, Yellow, Red, Blue, and Green. You can mix and blend them easily to make a custom color.

However, in my experience, I’ve seen that blue and red don’t entirely make purple because the tones don’t match. In that case, you should add a bit of white color to create a bond between them.

The best part of this ink is that it can stay vibrant for years after multiple washes. But you must ensure the material is properly heat pressed to make the stain permanent.

It works great on cotton, polyester, canvas, blends, rayon, linen, and synthetic materials. Apart from coverups, it also provides excellent cleanups using vinyl.

So, I’d recommend this screen printing ink if you’re looking for a reliable ink under $30.

Smalltongue Fabric Screen Printing Ink

Another great water-soluble screen printing ink is the Smalltongue Fabric Screen Printing ink. You can use it on cotton, blends, polyester, rayon, linen, and other synthetics. This ink is cost-efficient for both professional and personal uses.

You get 8 colors in this screen printing ink combo. The colors are White, Black, Purple, Yellow, Blue, Red, Brown, and Green. You can mix and blend these colors to make custom colors and also add water to reach your preferred thickness level.

The best thing about this screen printing is that it’s completely waterproof and won’t react to sunlight. But you need to wait for 24 hours to dry the paint completely before taking the material out in the sunlight or drenching it in water.

However, I didn’t like the strong smell coming out of the ink stains. But you don’t have to worry much about it since the odor fades away as the ink dries up.

2 Best Sublimation Inks

Hiipoo Sublimation Ink

Hiipoo Sublimation ink does the best job for on-demand sublimation printing. I’ve printed T-shirts, mugs, pillowcases, bags, and caps with this ink so far. They provide a great finish and a vibrant look after the printing is finished.

Apart from the items I’ve mentioned above, the ink also sits perfectly on shoes, quilts, ceramics, boxes, cross-stitched items, flags, and banners.

The black color comes in a 127ml bottle while the yellow, cyan, and magenta comes in 70 ml. This is great if you need to sublimate more in black and white colors. The packaging also makes zero clogs while transferring the ink. So, the printing turns out smooth.

Though this Hiipoo Sublimation ink is made for EcoTank Supertank Inkjet Printer, it also works great on other sublimation printers. But remember to drain out old inks from the printer before using the Hiipoo Sublimation Ink. Otherwise, the ink will get contaminated and you’ll not receive the desired finish.

Hiipoo Sublimation Ink Refilled Bottles

The second on my list is the Hippoo Sublimation Ink Refilled Bottles. Hiippo is also a master in these sublimation ink bottles that are inexpensive but provide reliable performance.

The packaging comes with 100ml of 4 basic printer ink colors. These inks are best for creating fine lines and fonts with vibrant colors.

They provide the same color accuracy as the original print sublimating on mugs, t-shirts, pillowcases, shoes, cross-stitch, banners, hats, ceramics, wine glasses, flip flops, mugs, socks, canvas, puzzles, wood, hoodies, etc.

What you’ll love about these inks is that they dry up really fast. They are also water-resistant and easy to use. So, you don’t have to worry about smudging them or washing them off after multiple washes.

Paired with a print head cleaning kit before filling the printer, these inks bring out the best printing effect.

Overall, the Hiippoo Sublimation Ink Refilled Bottles will be a great investment if you’re just starting out.

Facts about Screen Printing and Sublimation Printing

Now, as easy as screen printing and sublimation sound, you’ll be surprised to know about their roots, uses, and activities.

I’ve included 5 interesting facts about screen printing and sublimation printing below that you probably don’t know.

5 Facts about Screen Printing

Here are the 5 facts about screen printing given below.

- The Chinese Song Dynasty first started screen printing dating back from 960 to 1279 CE. Interestingly, they originated this printing skill to print money at that time.

- Screen Printing got popular for using on different kinds of substrate during the Second World War.

- The first promotional screen printing T-shirt was done for the famous film, The Wizard of Oz in 1939.

- Andy Warhol was the most influential screen printer who was renowned for his photographic silk printing techniques of celebrity images.

- T-shirts became widely popular across the globe after manufacturers started screen printing on cotton T-shirts. Now, annually it’s a billion-dollar industry.

Surprised enough? Wait until you learn about the interesting facts of the sublimation process.

5 Facts about Sublimation Printing

Check out these 5 facts about sublimation printing.

- Jabir ibn Hayyan (Gerber) first explained the sublimation process back in the 700s.

- The concept was revitalized after Noel de Plasse invented sublimation printing in 1957. It happened in a French textile company when he discovered that dyes sublimate.

- In technical language, sublimation is called dye diffusion.

- Sublimation process became popular during the 1960s when people started mass sublimating on different kinds of substrates.

- Sublimation printers need special tools built in to keep up with the ink’s consistency and temperature sensitivity.

What is Suitable for Your Business?

So, if you’re a small entrepreneur looking for options for starting out a printing business, you must be aware of both of the processes – screen printing and sublimation printing.

Based on the resources, skillset, and investment you have, the printing process will differ. Again, it also depends on the type of orders you want to fulfill for your customers.

For example, if you want to offer custom small order options, sublimation will be a suitable business for you. But if you want to work with bulk orders only, screen printing is the better option here.

So, to figure out which business will be suitable for you, here’s a checklist you can follow.

| Factors | Screen Printing | Sublimation |

| Custom Orders | Best for Bulk Orders | Best for Small or Single Orders |

| Investment | Requires expensive manual labor | Costs more in buying printing machines and heat presses. |

| Fabric Material Compatibility | Works best on cotton and cotton blends | Only works on 30% cotton fabrics |

| Diversity of Designs | Best for creating simple yet elegant designs | Applicable for all types of designs |

| Color Variations | Costs more for adding 2+ colors | The numbers of colors don’t matter in expenses |

Overall, I can’t declare any of the printing processes as the best in the business. Depending on your resources, availability, and investment, you have to choose what works best for you.

Cost Calculator – Screen Printing vs Sublimation

FAQs

Is screen printing more expensive than sublimation?

No, screen printing isn’t more expensive than sublimation. It takes around $6.64 to screen print a shirt whereas it costs around $10-$12 per shirt. But in case you add multiple colors in screen printing, it becomes expensive.

Is sublimation more durable than screen printing?

Yes, sublimation is more durable than screen printing. It’s because sublimation uses a special technique that embeds the ink directly in the substrate. So, the sublimated print becomes impossible to remove. On the other hand, screen printing forces the ink on the substrate. It creates a print texture that is likely to crack after a few usages.

What lasts longer screen printing or heat press?

Screen printing lasts longer than heat press printing. The reason is that the ink doesn’t penetrate the substrate as much as it does in screen printing. So, after a few washes, heat press printing fades away.

What materials can be printed on using screen printing vs sublimation?

Cotton and cotton blends can be printed using screen printing whereas polyester fabrics are printed by sublimation. You can also screen print papers and cardboard. On the other hand, sublimation is famous for printing on ceramic and enamel substrates.

Can sublimation be used to print on dark fabrics?

Yes, sublimation can be used to print on dark fabrics. But you can’t do it in the traditional way. For this, you need to first put a base layer of white heat transfer on the substrate. After that, you have to press the HTV. Then, you can sublimate.

Which method offers a wider range of color options, screen printing, or sublimation?

Screen printing offers a wider range of color options. You can screen print with any color you want. However, for sublimation, you can inject only 4 colors in the printer (black, cyan, yellow, and magenta). The printer will help in achieving your preferred color blend on the sublimation transfer paper.

How does the production speed of screen printing compare to sublimation?

Screen printing has a slower production speed compared to sublimation. It’s because screen printing needs more time in manual labor than sublimation. So, you can produce more prints in sublimation at the same time you produce screen prints.

Can metallic colors be printed using screen printing or sublimation?

Metallic colors can be printed easily by using screen printing. You can just use glittered silver or gold dyes for it. However, for sublimation, you’ll have to make some exceptions to the traditional sublimation process. To use metallic colors in sublimation, you need to heat press Holographic and Metallic garment films on the substrate.

Which method is better for printing photographic or complex designs?

Sublimation is better than screen printing for printing photographic or complex designs. Though it’s not impossible to print complex patterns through screen printing, it becomes difficult to handle the amount of ink. So, the screen print doesn’t exactly come out as the original design.

Can screen printing or sublimation be used to print on curved or irregularly shaped objects?

Yes, both screen printing and sublimation can be used to print on curved or irregularly shaped objects. But in this case, sublimation printing is easier to do than screen printing. The reason is that the mesh screens are usually rectangular framed. So, sometimes it becomes hard to screen print on curved surfaces.

Which method is better for achieving a specific print texture or finish?

The sublimation printing method is better than screen printing for achieving a specific seamless print texture or finish. As screen printing dyes the top of the substrate, the ink doesn’t entirely get absorbed. So, you can feel the texture of the print in screen printing.

Can screen printing or sublimation be used to print on natural fibers like cotton or linen?

Screen printing can be used to print on natural fibers like cotton or linen. But for sublimation, you can only sublimate on fabrics that have 30% cotton. Moreover, linen is also an acceptable substrate for sublimation.

Final Words

I tried to explain all the points regarding screen printing vs sublimation from a hobbyist and business point of view. From now on, hopefully, you don’t have any doubts about the two printing processes. I’d suggest investing in any of these printing methods as both of them have the potential for high returns. Whatever you do, I wish you the best of luck!